Cleveland Tin Project – Tasmania

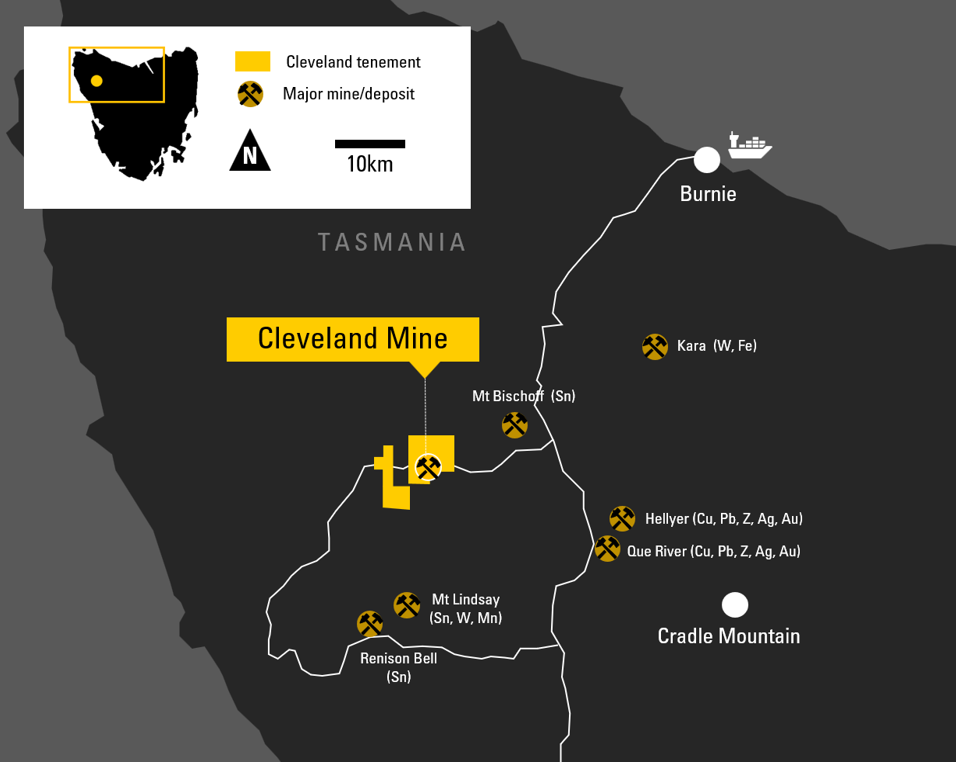

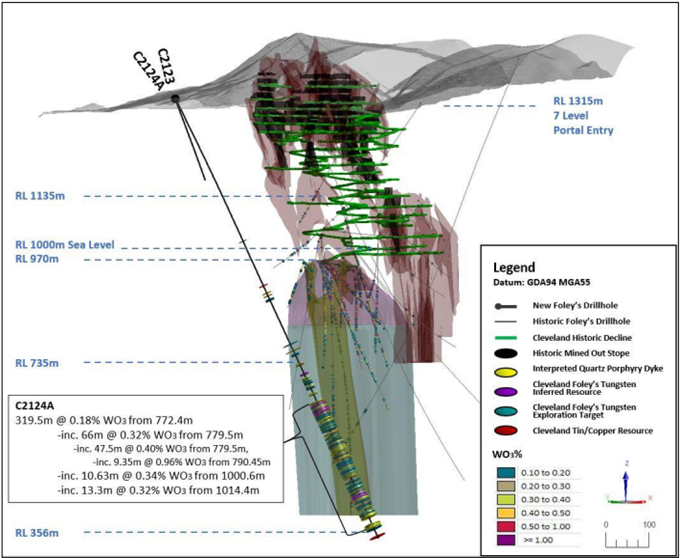

The Cleveland Tin Project is located 80km southwest of Burnie in the mineral-rich northwest region of Tasmania, Australia. The Cleveland mine is a historic (previously operating) underground tin mine still boasting a large Mineral Resource base and excellent access to electrical, water and transport infrastructure. Recent drilling has confirmed a large zone of Tungsten mineralisation and a suite of supporting Critical Minerals.

Site Location

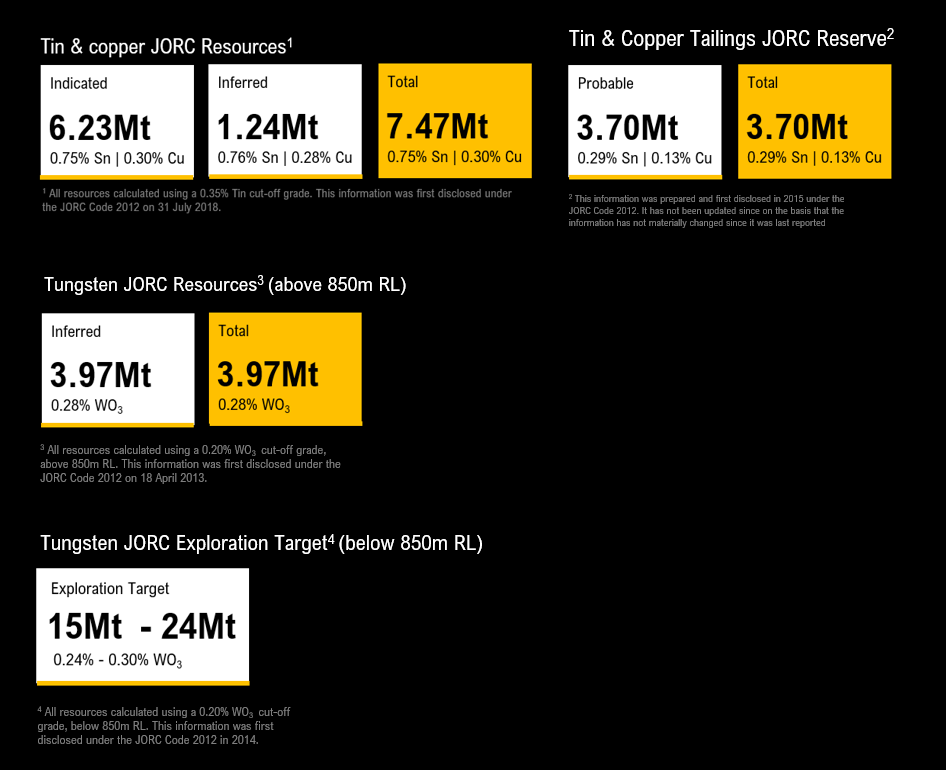

Cleveland Mineral Resources

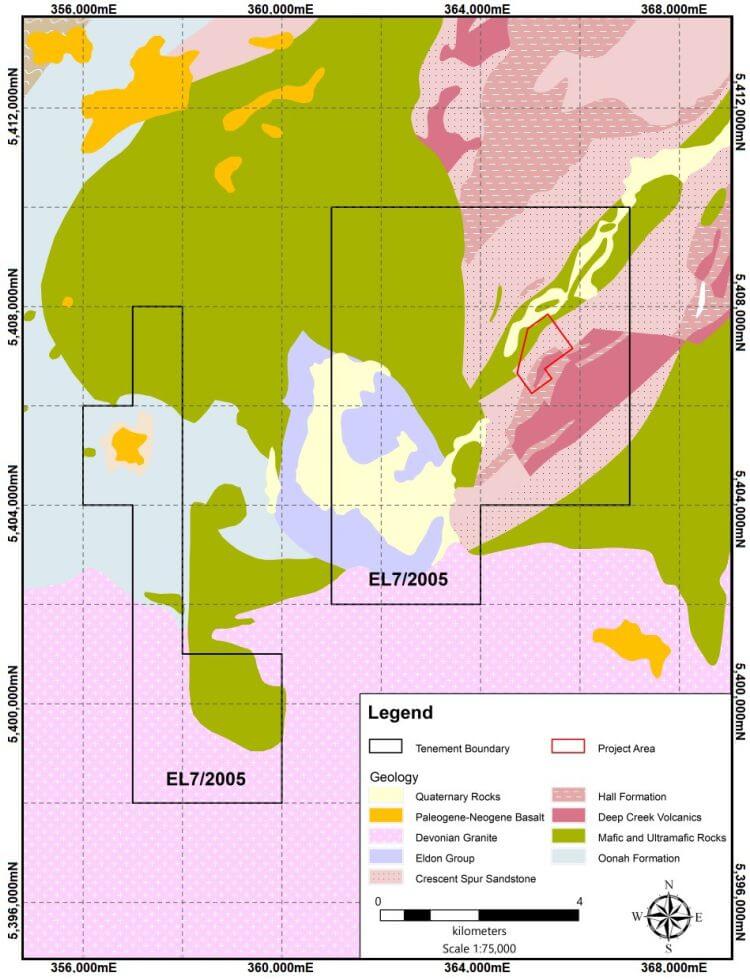

Cleveland Geology

– Stratiform semi-massive sulphide replacement ore lenses within a carbonaceous sedimentary package

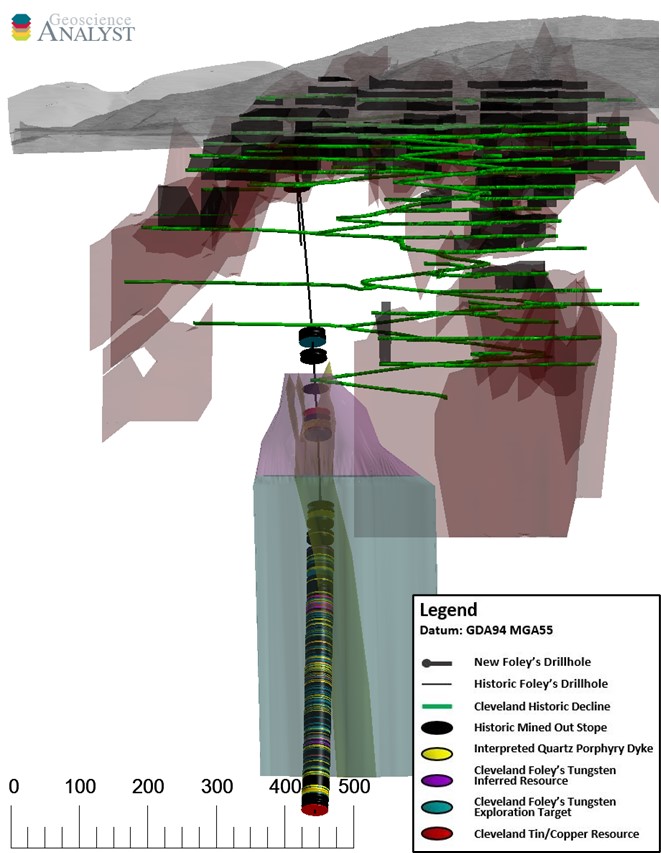

– Quartz porphyry hosted tungsten bearing quartz-stockwork, greisen orebody below 350m

– Principle sulphide mineral is pyrrhotite (magnetic) with cassiterite and minor stannite and chalcopyrite

Cleveland Tin Project History

Cleveland Tin Project operated as an underground mine from 1908 – 1917 and more recently by Aberfoyle Resources from 1968 – 1986.

The total ore mined to date is 5.65mt @ 0.68% Sn & 0.28% Cu, producing 23,519t of Sn and 9,691t of Cu. The mine closed in 1986.

Historical workings extend more than 400m below the surface. Mechanised sub-level overhead benching mining method was used. The conventional cassiterite recovery process of gravity followed by flotation was engaged, and the mine benefited from underground and surface infrastructure rehabilitation in1990.